Field Cut Instructions

The installed gasket direction is critical to performance. Install the gasket with the painted face marked “INSTALL THIS FACE OUT” pointing out of the bell and facing the installer.

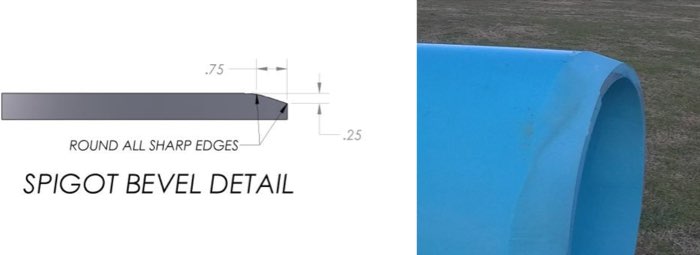

Field Cut Pipe and Bevel

If for any reason the factory bevel on the spigot end of the pipe is removed (e.g. the pipe is cut in the field to alter its length), a new bevel must be formed to aid assembly. This bevel may be formed by a variety of methods (e.g. a portable hand grinder) and need not be very substantial. A bevel depth of at least 1/4 inches deep by 3/4 inches long is sufficient.

Mark Assembly Depth

If the pipe does not have an assembly strip supplied by the manufacturer, measure from the lip of the bell to end of the socket. Subtract 1/2 inch from that. Place an assembly mark on the spigot this distance from the spigot end. This distance may vary by pipe manufacturer.

The joint may now be assembled according to the standard practices described in the RieberLok® Assembly Instructions

Download Instructions (PDF)